Scientists from Japan’s National Institute of Advanced Industrial Science and Technology have investigated the prospects for lightweight, flexible PV devices based on copper, indium, gallium and selenium (CIGS) thin-film technology.

The described their findings in “Lightweight and flexible Cu(In,Ga)Se2 solar minimodules: toward 20% photovoltaic efficiency and beyond,” which was recently published in Flexible Electronics. They said that their work was largely limited to panels that can be used on rooftops where severe weight restrictions are applied. However, they also used rooftops with curved surfaces and surfaces on which conventional crystalline silicon (c-Si) panels cannot be used.

“Among thin-film photovoltaic technologies, CIGS-based solar cells are an attractive option owing to their advantages of relatively high energy conversion efficiency, long-term stability, relatively short energy payback time, and small carbon footprint of products,” the scientists said.

It will be crucial to improve the control of alkali metal doping on the CIGS film, in order to help the CIGS solar module technology reach an efficiency of over 20% at the module level. They said this depends on the alkali metal species and the doping methods and processes.

“In addition to alkali-metal doping, silver (Ag)- and sulfur (S)-alloying for the modification and control of the energy band structure in CIGS devices, improvement in the bulk crystal quality, and surface and back interface modification are the current topics of interest in the CIGS community,” the scientists explained, noting that these techniques could help to increase the average efficiency of CIGS flexible panels from around 18.5% at present to more than 20%.

The scientists said the suppression of carrier recombination at the interface and in the bulk of a CIGS cell is one of the factors that must be improved to obtain higher efficiency. They identified scribed edges of CIGS photoabsorbers as one of the possible causes leading to recombination issues.

“Nevertheless, to date, there have been only a few discussions on the effect of mechanically scribed edges on photovoltaic performance,” they said. “Therefore, in this section, the effect of mechanical scribing (MS), which has been used as a standard technique, on photovoltaic performance is comparatively studied with photolithographically formed edges.”

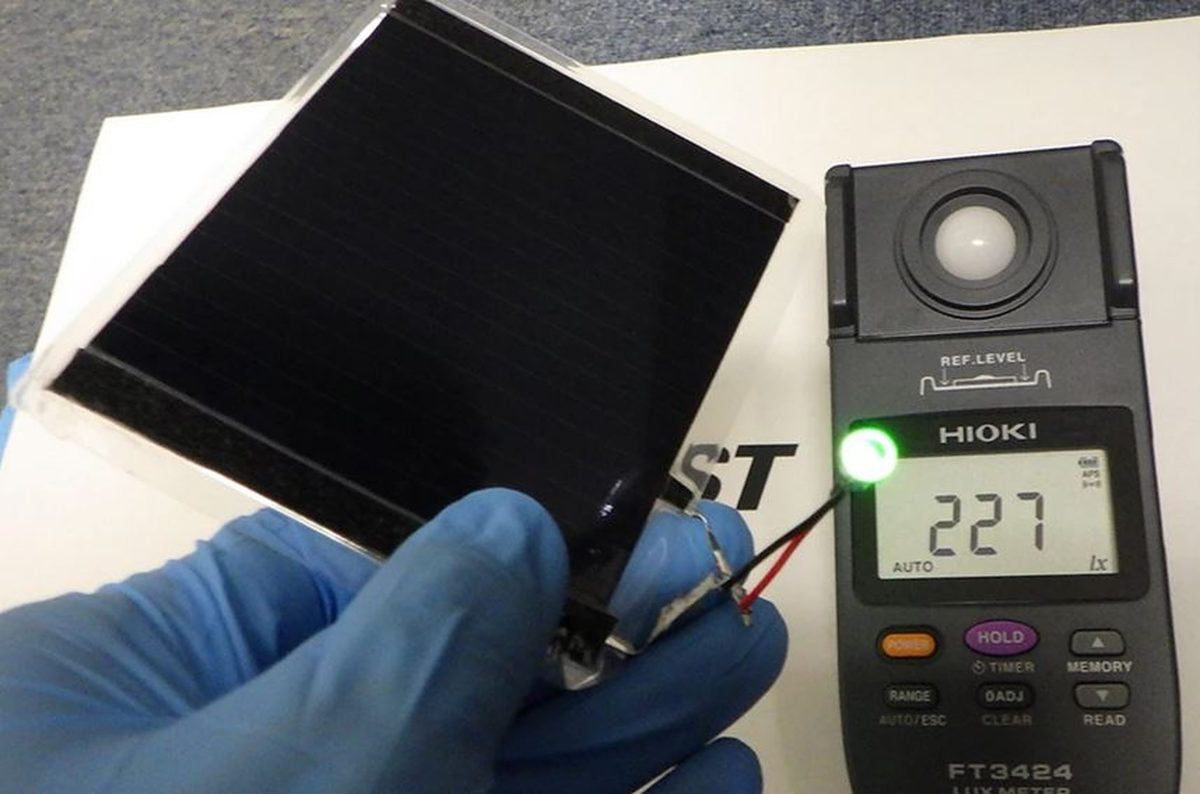

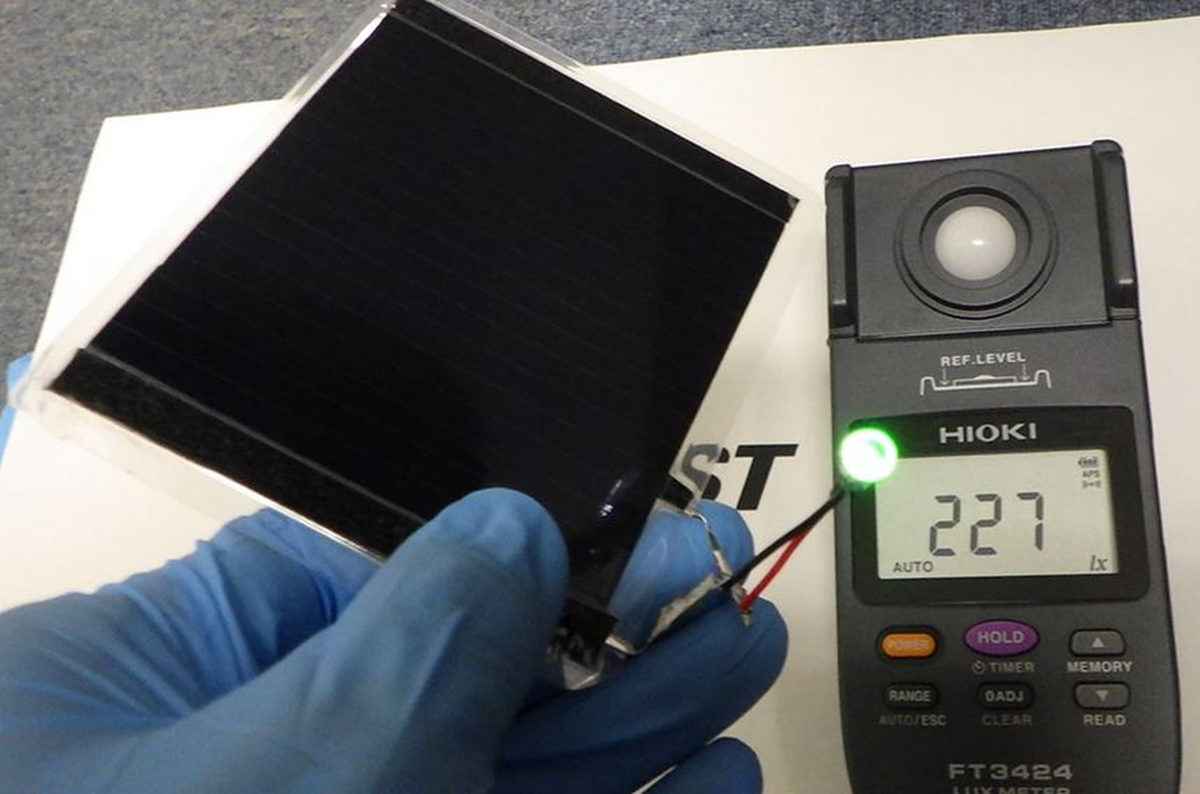

The review also investigates the variations in CIGS performance with light intensity and suggests the usefulness of CIGS photovoltaic devices under low illumination conditions.

“For further development, the improvement of CIGS single-cell performance is essential,” they concluded. “Approaches based on material science and device physics, including modification of surface and interface, and bulk crystal quality by alloying with Ag or S, or other elements as well as doping control of alkali metals, are expected to bring further progress in CIGS photovoltaics.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.